One of the last projects standing in the way of turning the key (as well as seeing if all of my wiring was done correctly).

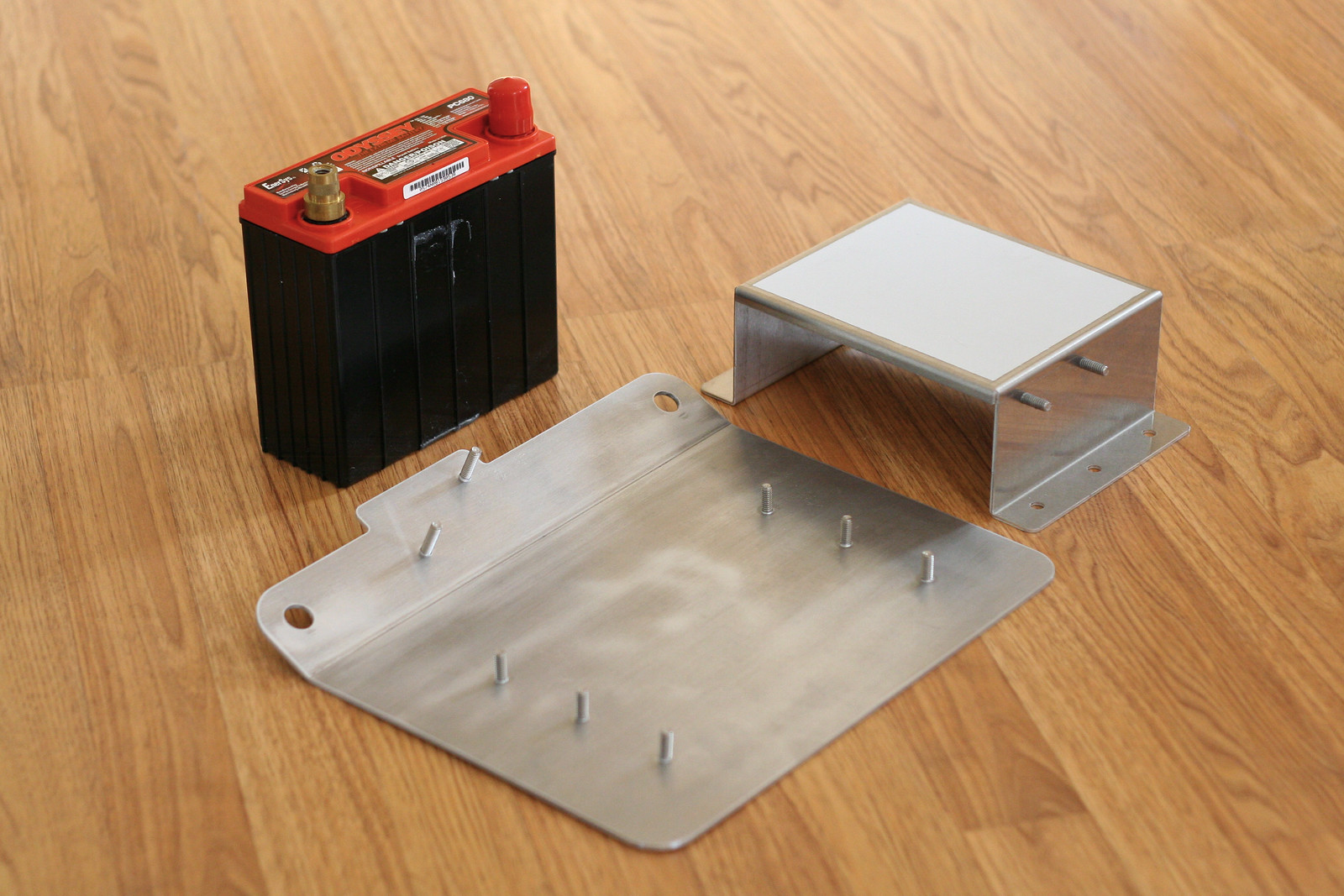

Like my other wiring projects, this one has served as an in-depth lesson in automotive electrical systems. And like everything else with this build, a project as simple as relocating a battery quickly snowballed. It seems to be common practice for batteries to migrate from the stock location (the engine bay in a Saturn S-Series) to the trunk. However, a known water leak made me weary of placing the core of the electrical system back there. With the rear half of the car empty I had plenty of room for an alternate setup. Power will come from an Odyssey PC680 dry cell battery, chosen for its smaller dimensions and positive track record with other Saturn builders. Accompanying the Odyssey are some additional precautionary components (pictured below from left to right):

- Bussmann 100 amp resettable circuit breaker (CB185-100)

- Allstar Performance Ford-style remote starter solenoid (ALL76203)

- Moroso 4-post battery cutoff switch (74102)

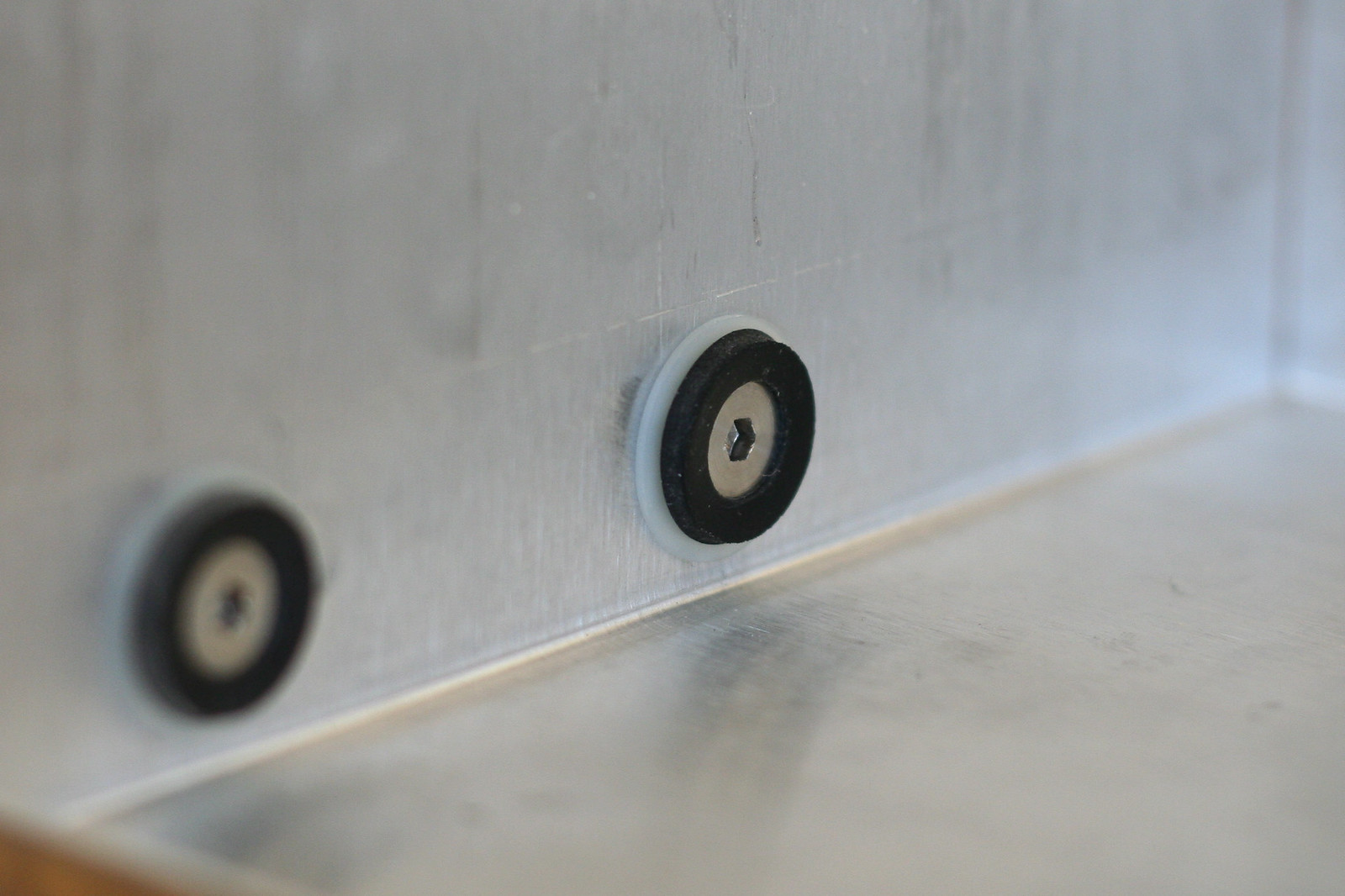

Looking back at the first picture, I designed a simple tray to accommodate the battery and breaker that would take advantage of existing mounting points in the car (in this case, the rear belt buckle mounting studs). Holes were laid out on a cardboard template to match those on the Bussmann breaker and a bent aluminum battery hold down (available for purchase from Odyssey). Once I was satisfied with my mockup, the geometry was recreated in AutoCAD and forwarded to Jeremy (whose work can be seen in an earlier post) to get cut and bent. The holes for the breaker and hold were sized to accept stainless steel 1/4"-20 PEM studs from McMaster-Carr. On the side of the battery hold down there are what appear to be more studs; due to the shape of the hold down, there was no way to press in a pair of PEM studs. These are actually modified low profile socket head cap screws for the Allstar solenoid.

Much to my benefit the hold down had a loose fit over the battery. After removing additional material from the already-shallow (roughly 1/8") screw heads, there was just enough room to clear the battery. With the modified hardware threaded into place, a rubber washer backed by a nylon spacer was added for peace of mind against any damage to the battery. Lastly (pictured below) are my crude brackets for mounting the Moroso cutoff switch and an insulated terminal block. Both of these pieces will be elaborated on later.

No comments:

Post a Comment