This project was good practice for a few different machining procedures. The results weren't perfect but were pretty good for a novice (nor would they affect the performance of the shifter).

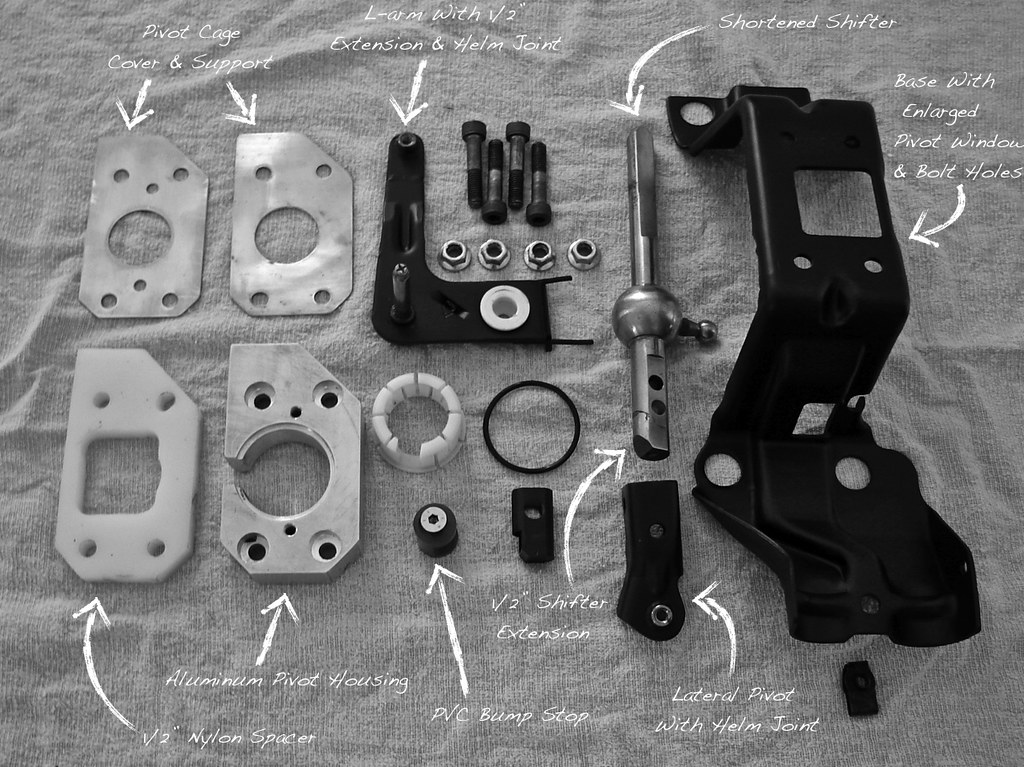

Shifter Build, August 18th, 2010: "I am a little overdue to add this to my build thread. Some of you probably already saw it in the thread I had in the 'Performance' section. Anyway I had previously built a nice short throw shifter for the SL2 in high school but the opportunity arose to build an ever better one. Dad had built a trick unit for the TDI but couldn't science out the reverse lock the Volkswagens have. At my disposal I had a shifter with a machined aluminum pivot housing (for the plastic cage) and lower pivot points with mounting for helm joints. The catch was the shifter was essentially backwards from a Saturn shifter. I scored up an unmolested shifter from Justin (d3ad1ysp0rk) and set aside everything I would need from the two shifters. On the stock base I enlarged the window to clear the movements of the main pivot, drilled out the four mounting holes for larger hardware, and made a notch for the helm joint on the L-arm to pass through. To make use of the L-arm the helm pivot from the TDI shifter was cut off and welded to the Saturn L-arm 1/2" lower than stock. The aluminum block had to be flipped over with the lip for the plastic cage re-machined (accomplished on my fathers lathe), the holes for the four bolts re-countersunk, and a hole for a "bumper" drilled and tap. The bumper was added to properly restrict vertical movement of the L-arm (like the tab on the stock plastic pivot housings). I made the bumper out of a piece of grey PVC, notched to clear the L-arm movements, and countersunk on one end for a flush fit of the mounting hardware. The other pivot point was extended by adding a 1/2" of material to the base of the shifter rod (TIG welded), re-machining the flats, and re-drilling the hole to mount the inner pivot; accomplished with a hex-head through-bolt with one side of the inner pivot threaded. The top of the shifter was cut down and the flats/notches for the shift knob were re-created with by hand with a mill file. The last piece I made was a plate to go over the top of the shifter base to help secure the plastic cage. Other pre-existing details include the 1/2" nylon spacer (to raise the main pivot) and a bronze bushing for the L-arm pivot (secured by a stainless steel nylon nut). The shifter still isn't in the car as I still need to purchase the helm joints to modify the shifter cables. Lately I've been plowing through the wiring to the gauge cluster, which is almost done, so hopefully I'll have another update soon."