This is a project that I am particularly proud of. At the time of the original posting I was still working out my wiring which I eventually wrapped up in August/September (these posts have been included at the bottom).

Gauge Cluster Build, June 8th, 2010: "I dreamed up this set-up awhile ago and it evolved a little bit throughout the building process. It initially started with the 3G head unit which I purchased years ago (since the SL2 is down to the two front speakers audio isn't a big deal in this car). I knew I wanted to make it appear OEM in fitment and that to do so I was going to have to alter the trim bezel. Fast forward to the past couple of months; I had toyed around with lots of different mounting solutions for the gauges but ultimately decided I wanted to consolidate them right in front of me. To have the room to put all of the gauges in one place I would have to mount the radio as low as possible. This was accomplished by resting the unit in the cradle of the original 94' radio with some shims to get the unit where I wanted it, then altering the 3G brackets to tie into the mounting points at the top of the climate control. There is a slight curvature to the bottom edge of the radio face on the 3G unit so I have it sitting in a way that it pretty much sits on the bridge right below it. I had debated trying to recreate this curve on the actual bezel but found it much simpler to do it the way described. Fortunately the upper edge of the radio face was straight. I also filled in the holes at the top of the bezel where the adjustment wheels for the vents used to be.

After the unit mounting was settled I moved onto the altering the bezel. I had been sitting on a few of these bezels with one that was mint (really just no broken clips) and two others for material. After some measurements I cut up the spare bezel for the bridge that runs across the top of the radio and did some trimming to the good bezel so I could graft it in. Everything was mated together with plastic epoxy as well as reinforced over the joints on the backside to ensure things were secure. Once all was said and done I was able to cut out all of the unused bridging to make room for the gauges. Of course there was a ton of finish work involved. I spent a lot of time knocking down the plastic materials textured finish with 400 grit and used a few coats of Kyrlon Plastic Fusion to fill any blemishs with a sanding and final coat.

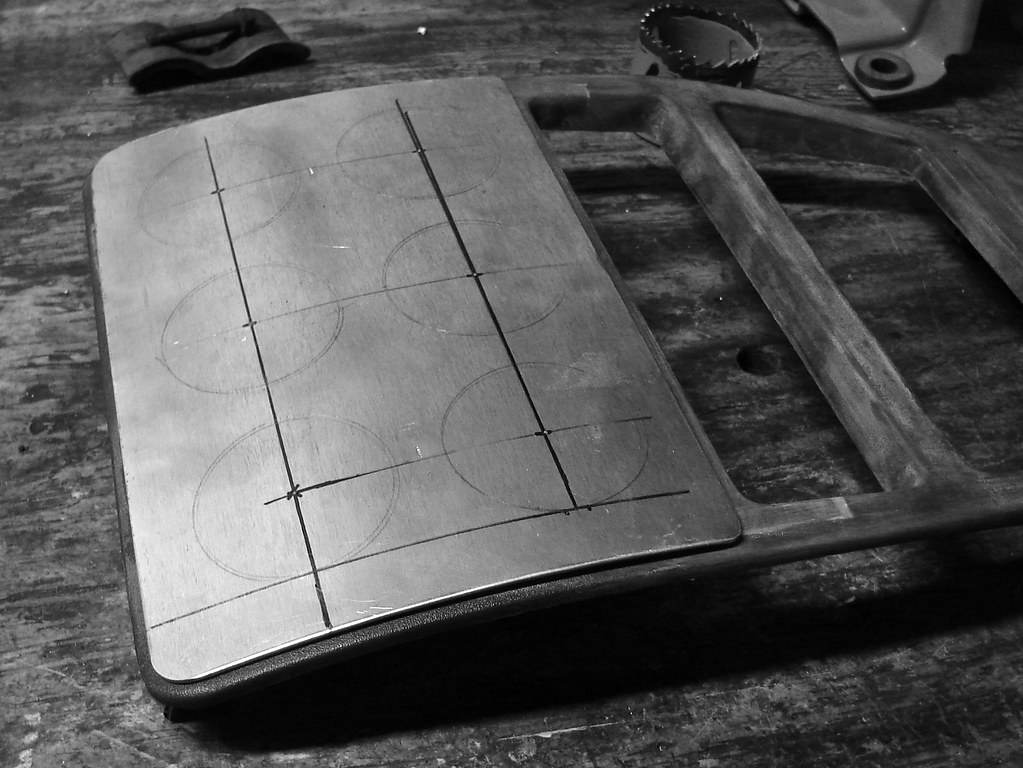

The plate the gauges are mounted in is just a sheet of aluminum (1/8" I think) my Dad sheered up for me. This started out as a cardboard template after finishing up the area around the radio. It should have been pretty straight forward but the way the bezel is shaped made nothing square. I was actually quite paranoid that I had take incorrect measurements while doing the graft but after triple-checking everything I determined it was just the way the bezel is. So while laying out everything I had to make adjustments to maintain the illusion that nothing was crooked. Once done with cardboard I duplicated it in aluminum. I trimmed the edges first, then duplicated the slight curvature of the bezel by bending it over an old fire extinguisher. I cut the holes afterward to compensate for any distortion from the bending (which honestly wasn't all that much).

At first I was going to just have it powdercoated in a textured black finish but changed my mind while flipping through some street rodding books. I had seen a dash that was wrapped in vinyl with the button head hardware and though it had a touch of class while appearing purely functional so I adapted what I saw. The vinyl also gave the gauges a little extra something to seat into as the aren't on an entirely flat service. The material also dimpled around the hardware which gives the whole thing a little extra depth. The vinyl wrapped panel is secured to the panel by the visible hardware all the way around. I am still on fence as to whether the stuff I used to big but it was the smallest I could find locally. I also backed the existed mounting points (dash-to-bezel clips) with some velcro. I have to go back and make some adjustments to the radio as there is a small gap at the bottom of the face..."

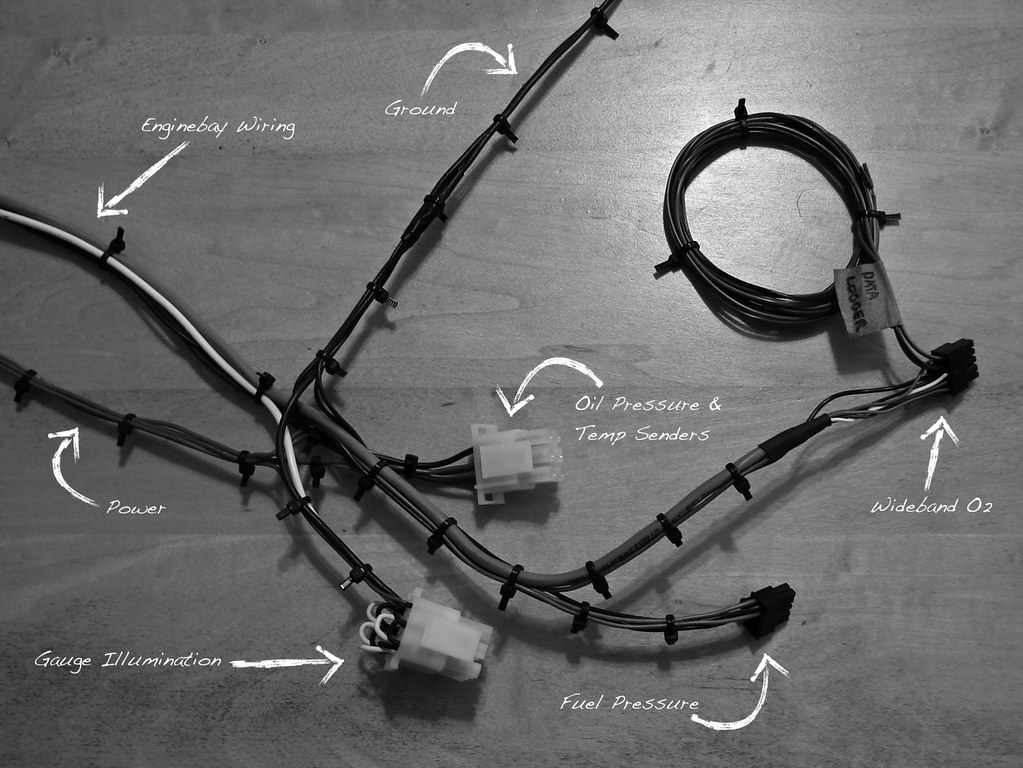

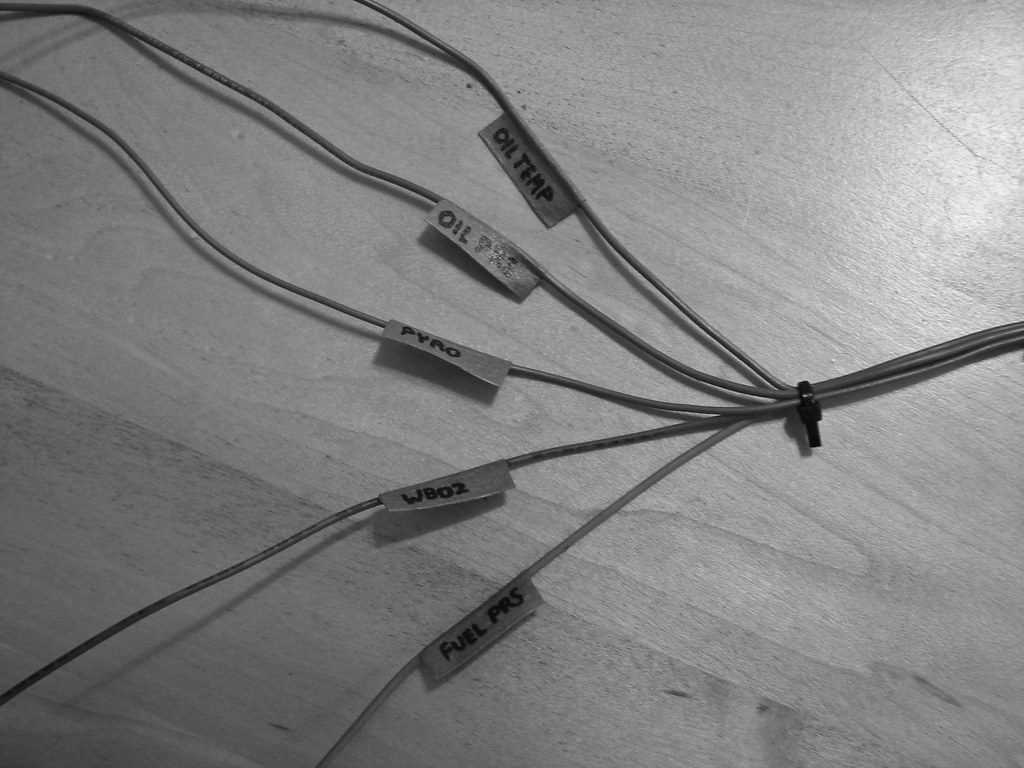

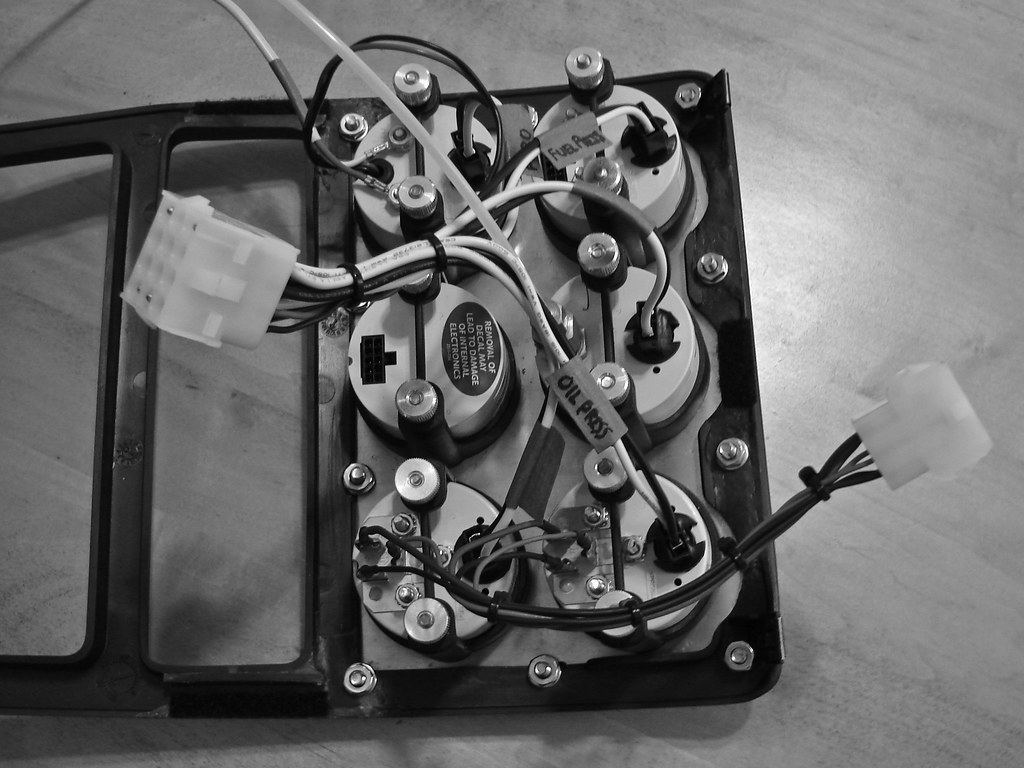

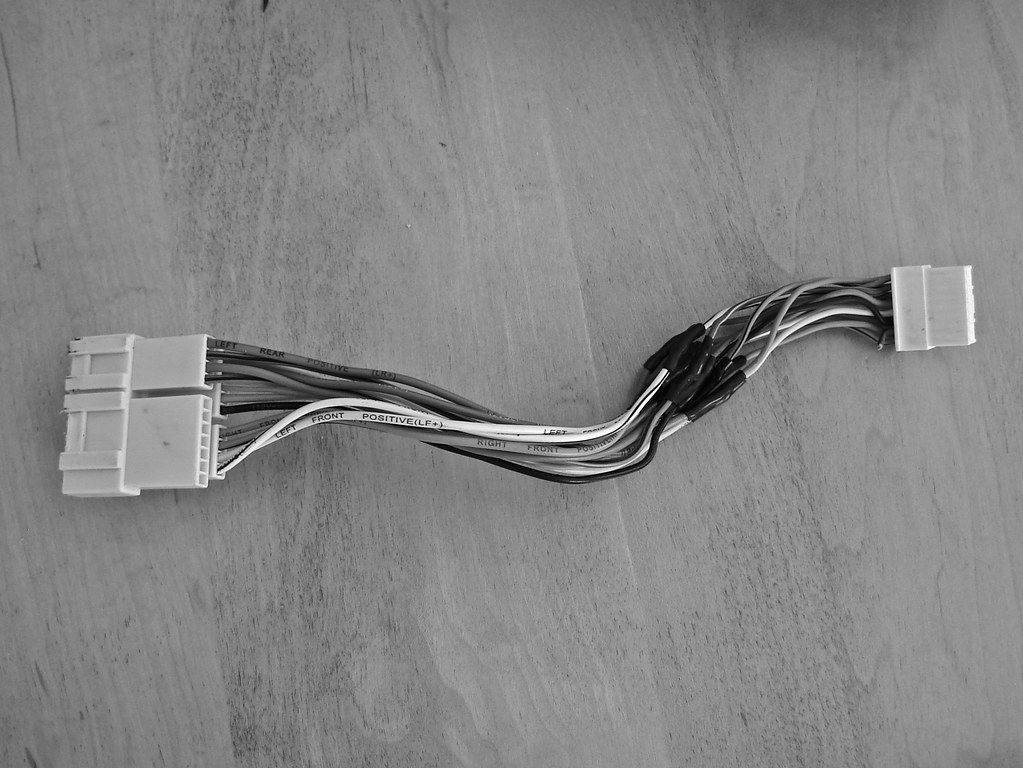

Gauge Cluster Wiring, August 16th, 2010: "I've finally gotten somewhere with the wiring for my Autometer gauge cluster. To be honest I didn't have a clue as to how to tackle wiring for six gauges other than knowing I want a clean execution. What you see grew out of a single starting point and I am pretty pleased with the outcome. When I started I knew that I didn't want the gauges to be "hard wired" into the car in the even that I need to remove the cluster for servicing. With this in mind I began by pinning out any wiring that didn't come as a plug in affair. This included all of the wiring for illumination and the power/ground wires fixed in the back of the Pyrometer now all in a 12-pin plug. The connections for power, ground, and sending units on the back of the oil pressure and temperature gauges had spades for press-on terminals so I dug out some color coordinated wires (red for power, black for ground, purple for pressure, blue for temperature) and soldered press on terminals on the gauge end and pins for a 6-pin plug on the other. When I was done with the female plug ends I started the harness for the male halves of the 6-pin and 12-pin plugs. To keep things simple I made jumpers from single leads to plug into the appropriate pins (you can best see this with the white illumination/black ground wiring in the bottom plug in the first picture). The WBO2 and fuel pressure gauges came with their own plugs (the two small black ones, first picture) and with my own plugs done I plugged everything into the back of the cluster to merge with zip-ties. From the overall harness I separated all of my power wires which will go to their own fuse strip (which I still need to purchase). To ground everything I found a nice two wire bolt-on spade that I tied into each of my own plugs (seen going off the top of the first picture). The rest of the wiring will go through the firewall to the engine bays where everything will be connected to their senders/sensors and so on."

Gauge Cluster Updates, September 27th, 2010: "Been busy wrapping up some of the previously posted projects and starting others. I received an antenna adapter for the 3G head unit earlier in the week. The lack-of had been holding me up from doing the final install of the altered bezel/gauge cluster as I didn't want to keep taking things apart. Since I had to pull the radio I double checked my adapter harness and wrapped it in some plastic loom for the final install. I also took the chance for some pictures of my radio brackets and adapter harness.

Plugging in all my gauges was a little tricky with everything being a bit bulky but went together well otherwise. Sometime in the future I will have to take things apart to create additional mounting points for the bezel. As mentioned in an earlier post the weight of the six gauges is working against the factory clips. In addition the wiring is also pushing outward on the back of the gauges. I had aided the install with some velcro but the whole thing isn't as secure as I'd like. Wiring for the pyrometer and the hose for the boost gauge have been added to the growing sub-harness that goes through the grommet in the firewall. I spent some time zip-tying that on the interior side. Aside from a wire for a future manual fan switch I should be done shoving a coat hangar through there."