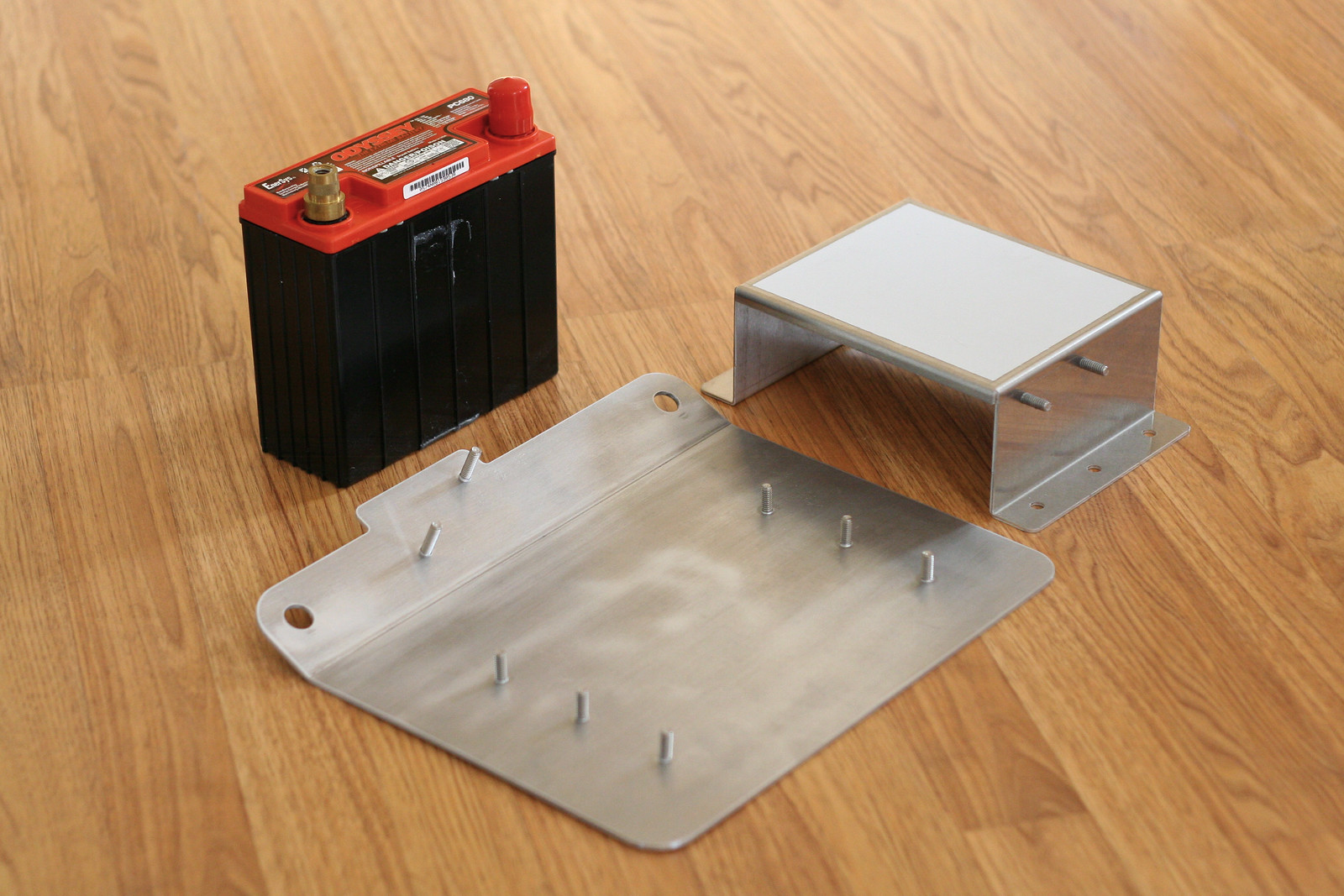

One of the last projects standing in the way of turning the key (as well as seeing if all of my wiring was done correctly).

May 28, 2013

Electrical Component Preview

May 10, 2013

Another Length Of Exhaust

Already done is the next 3' (a little under actually, measuring at 33") of the exhaust system.

I'm going to call this piece the midpipe, the portion of exhaust that includes a flex section and the catalytic convertor. The flex section is a Vibrant item, 6" in overall length with a 3" in diameter and an interlocking liner while the catalytic convertor is a metal core unit, also from Vibrant, with a matching diameter and 10" overall length. To help tuck the exhaust system up under the car, I utilized two 15 degree bends. Everything is 304 stainless steel, of course! The final length of the assembly is entirely random. To keep the catalytic convertor a little closer to the front of the car, I shortened the leg of the bend right before it. The length after the catalytic convertor comes from the longest piece (6.5") of extra tubing I happened to have kicking around. It was an early decision to make this area of the exhaust system its own sub assembly, not only for a less cumbersome solo installation, but to make transport to the welder a little easier for the remaining (and now shorter) exhaust system. The last remaining detail is a hangar to utilize the stock hangar arrangement. I won't be designing that until the rest of the exhaust is ready and I can do all of the hangars in a batch.

I'm going to call this piece the midpipe, the portion of exhaust that includes a flex section and the catalytic convertor. The flex section is a Vibrant item, 6" in overall length with a 3" in diameter and an interlocking liner while the catalytic convertor is a metal core unit, also from Vibrant, with a matching diameter and 10" overall length. To help tuck the exhaust system up under the car, I utilized two 15 degree bends. Everything is 304 stainless steel, of course! The final length of the assembly is entirely random. To keep the catalytic convertor a little closer to the front of the car, I shortened the leg of the bend right before it. The length after the catalytic convertor comes from the longest piece (6.5") of extra tubing I happened to have kicking around. It was an early decision to make this area of the exhaust system its own sub assembly, not only for a less cumbersome solo installation, but to make transport to the welder a little easier for the remaining (and now shorter) exhaust system. The last remaining detail is a hangar to utilize the stock hangar arrangement. I won't be designing that until the rest of the exhaust is ready and I can do all of the hangars in a batch.

May 05, 2013

Oil Catch Can, Welded Up

It took a few trips, but the catch can is all fried up!

I actually fell a few steps back after discovering that my spacing for the internal baffling put the bottom most disc right in the way of the oil drain fitting. This wouldn't had been a big deal, except for making the discovery after having the aluminum nuts tack welded into place. Needless to say, I was at least able to save the perforated discs. Another order with McMaster Carr later, and I had a new and improved version of the baffling - this time I opted to loctite the top nut into place, and eliminate the bottom nut by having the stem of the assembly welded to the base of the catch can.

May 01, 2013

Downpipe Revisited

Sometime in February I discovered that the downpipe wasn't quite done yet.

Embarrassingly, I had a bit of an oversight with my placement of the oultet v-band flange when I originally fabricated the thing. As I found it, where it ended up next to the oil pan, was too tight to get the v-band clamp on. How I didn't see this the first time I'm not sure, but after a face-palm, some choice words, and removing the wastegate/dump tube assembly the downpipe was back out again. To remedy the problem involved extending the length by 6" to push the flange out into a more open area. Fortunately I had plenty of spare material kicking around, although it meant sacrificing the v-band flange that was on there. The extra length did create another situation however. In the same fashion as a stock Saturn downpipe, I had wanted to add a bracket to secure the exhaust against the two rearward most mounting points of the transaxle-motor brace. Originally I was going to save this additional bracket for the next length of exhaust, but since the downpipe was now passing under these points I would be adding it to the extension.

Subscribe to:

Comments (Atom)